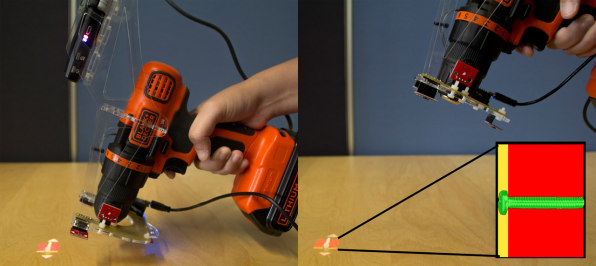

Known for using recycled skateboards to create functional products and accessories, Chops helps show the process of manufacturing these durable boards. Use this video to create this project on any Laguna CNC router! Join us as we team up with Chops MFG to create our latest CNC woodworking project - a skateboard jig and DIY press to complete a skateboard deck. Huge thank you to Shane from Shane’s Hardwood for putting together this build!

Natural elements, including an oversized pinecone cut by the Laguna 14|BX bandsaw, provide a fresh design on this advanced CNC woodworking project. This video features each step in the process of the build, from fly cutting the materials to finishing off the epoxy pour and installing the table tops. Take a look as a slab of Oak transforms into a beautiful, custom bar top with natural accents, set into layers of resin epoxy.

#Smart tool shop pro#

You'll come to see that cabinet making is a very simple process as we quickly put the blueprint together on CabinetSense software, add finishing touches on VCarve Pro software, cut it out on the CNC, and then assemble it.ġ:47 Designing upper cabinet (selecting door, placing new shelves, and changing measurements)ģ:46 Designing base cabinet (placing internal parts, tailoring shelves, adding drawers, and changing measurements)Ĩ:49 Importing cabinet file in VCarve Pro vetric softwareġ0:14 Nest all the parts onto the material The video will be equal parts training and demonstration, with the explanation being left unedited, so you can get a good sense of what it takes to complete a standard construction.

#Smart tool shop how to#

In this How To video tutorial we will cover all the basics to design, cut, and build cabinets using a CNC router. Shout out to Jack's Woodworking Designs for putting together the construction of the parametric wall! Check out his website here: The 130" wide built-in benches were the final element to conclude the structure was the perfect custom piece for a modern reception area. The wave-like shapes cut out by the SmartShop® M then create an aesthetic, 3D accent wall measuring 40' wide and 103" tall with a matching desk, giving the space they reside in a unique feel of movement. This video demonstrates that with a creative, yet simple idea, a CNC router becomes a useful asset in the construction of what seems like a complex build. What first starts as a pile of 4'x10' maple plywood sheets incredibly transforms into a multi-dimensional, parametric wall consisting of hundreds of layers, 289 panels to be exact. ►Contact us for more info: 800.234.1976 or email: Ġ:00 Intro to making wine rack table with CNC vacuum fixturesĠ:30 Previewing vacuum fixture on Aspire softwareġ:03 Flycutting test to ensure enough suction powerĨ:26 Finishing touches and assembled wine rack Subscribe to our CNC email list for deals and promotions: Follow along as we show the process of machining each part and assembling it into a simple yet sophisticated, live edge wine storage table!įind the SmartShop® SUV and other CNCs on sale during March Machine Madness: Complete with tips on how to make CNC vacuum fixtures, this video serves as a tool for other future furniture making projects. In this video we'll demonstrate the essentials to building your own custom wine rack on a CNC router.

0 kommentar(er)

0 kommentar(er)